Time:6 2023

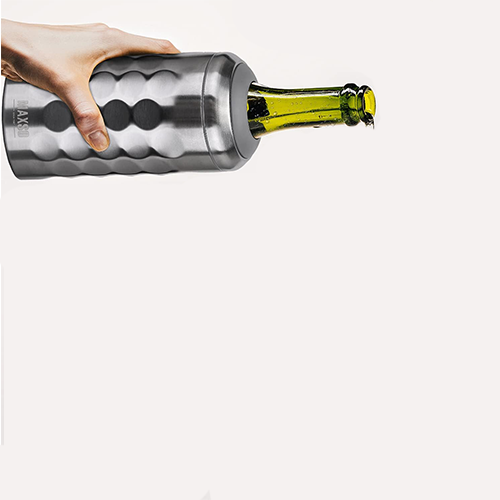

Electroplated red wine glass bottle is a kind of product coated with a layer of metal film on the surface of ordinary glass bottles, which has the characteristics of high grade, beautiful, ultraviolet protection, etc., and is widely used for packaging high-end red wine. The manufacturing process of electroplated red wine glass bottles mainly includes the following steps:

The production of glass bottles. The production process of glass bottles mainly includes raw material ratio, melting, molding, annealing, inspection and other links. The raw material ratio is to mix the main raw materials such as sand, soda ash, limestone and auxiliary raw materials such as broken glass in a certain proportion to ensure the quality and performance of the glass. Melting is the continuous heating of the raw material mixture at high temperature to form a uniform glass liquid. Molding is to shape the glass liquid into the desired glass bottle shape by cutting, pressing or blowing. Annealing is the process of reheating the glass bottle after forming and slowly cooling it to eliminate internal stress and increase strength and stability. Inspection is the quality inspection of the appearance, size, thickness, capacity and other aspects of the glass bottle, and the removal of unqualified products.

Wash and dry glass bottles. In order to ensure the electroplating effect, it is necessary to clean and dry the glass bottles to remove impurities such as dust, oil and water stains on the surface. Washing can be done by washing or solvent washing, and drying can be done by natural air drying or mechanical dry.

Plating of glass bottles. Electroplating is the process of depositing a metal film on the surface of glass by electrolysis. Electroplating can be divided into two ways: vacuum electroplating and chemical electroplating. Vacuum electroplating is the evaporation of metal materials in a vacuum environment by heating, and then transported to the glass surface by low pressure gas or inert gas to form a metal film. Chemical electroplating is to use metal salt solution as electrolyte, direct current is passed between electrodes, so that metal ions are reduced and deposited on the glass surface to form a metal film. Commonly used electroplating metals are aluminum, copper, silver, gold, etc., can be selected according to the need for different colors and luster.

Post-treatment and inspection of glass bottles. In order to improve the adhesion and durability of the coating, it is necessary to post-treat the glass after electroplating, such as spraying protective paint, polishing and waxing. At the same time, it is also necessary to test the thickness, color, brightness and other aspects of the coating to ensure that it meets the standards and requirements.