Electroplated glass bottle refers to the process of using electrophoresis to coat the glass surface with a layer of metal or alloy, the coating is generally gray. Electroplated glass bottle is more common in life, mainly because it has good ornamental value and collection value, is loved by a lot of people. Let's learn more about it.

I. Production process of electroplated glass wine bottle:

1. Procurement of raw materials (mainly iron and copper);

2. Cleaning and processing;

3. Raw material treatment;

4, electroplating pretreatment (including: surface pretreatment, chemical derusting, passivation and electric oil removal);

5, electroless copper plating, nickel plating;

6, cleaning processing (including: cleaning pickling, washing, drying);

7. Post-cleaning treatment (including water washing, oil removal, phosphating and water washing);

10. Packaging.

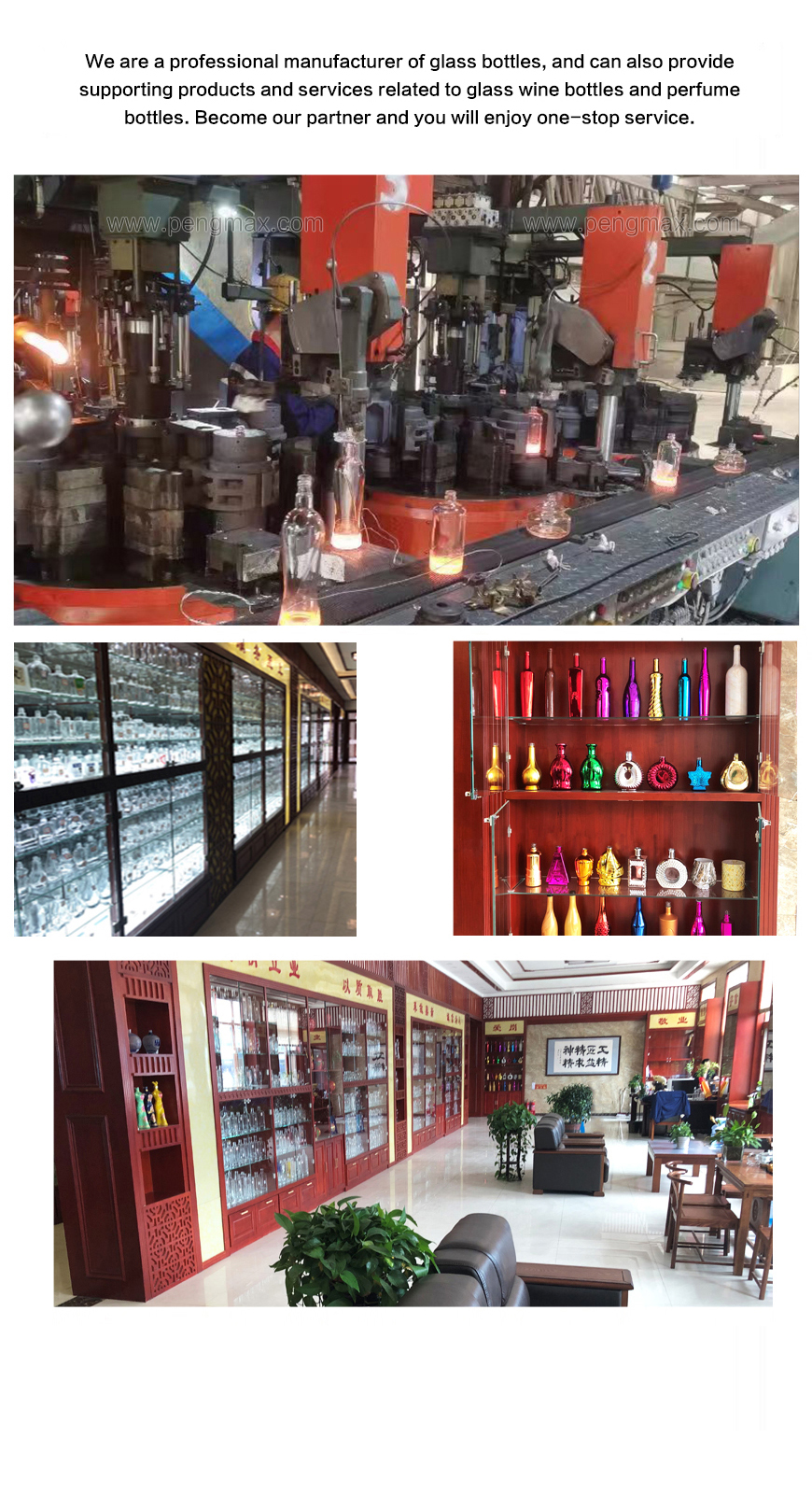

Decorative glass bottles: can be used as high-end wine bottles, with a variety of colors matching glass products, can not only decorate wine packaging bottles, but also can be used as high-end wine utensils. The main function of the electroplated glass wine bottle is to form a solid coating on its surface. Electroplated glass bottles are made of metal and glass. Electroplated glass bottles come in a variety of shapes. Electroplated glass bottles can be used as collection bottles and gift bottles. In appearance can be designed into a variety of different shapes. In addition, because of its special metallic color, it can also be used for special occasion packaging.